Manufacturing in a modern warehouse requires a high level of agility, precision, and flawless cooperation across all divisions. PassionIOT, a reputable company in the field of intelligent warehousing and material management, provides cutting-edge systems that are specifically designed to meet these requirements. They have an SMD storage system that allows for continuous production while reducing the amount of material waste and errors caused by humans.

As production lines grow more complex, PassionIOT’s solutions have become essential for brands like Xiaomi, Foxconn, and Midea. These companies rely on PassionIOT’s SMD storage system to stabilize output and handle high-mix, high-volume assembly environments with confidence.

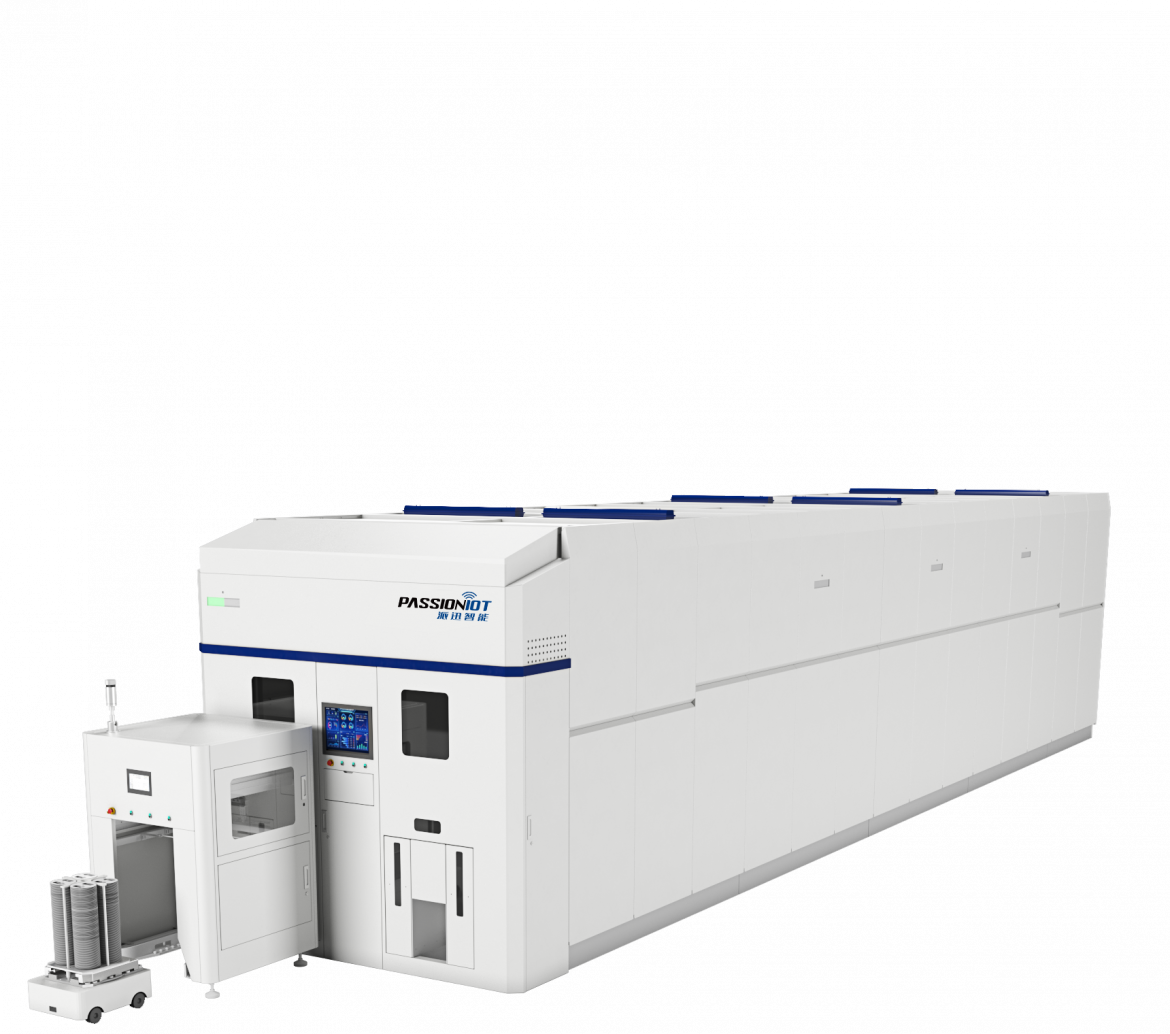

Efficient SMD Storage Systems for Demanding Workflows

The SMD storage system offered by PassionIOT simplifies component access and ensures timely delivery to the production line. Real-time inventory visibility and system-driven distribution reduce downtime and boost productivity across every phase of warehouse manufacturing.

The systems are built for flexibility, with modular design allowing quick adaptation to production changes. Integration with existing MES and ERP platforms ensures full traceability from receiving to final assembly.

From Smart Storage to Strategic Advantage

PassionIOT’s SMD lineside storage solutions have reshaped expectations for what intelligent storage can achieve. By supporting the development of Lighthouse Factories and Lights-Out operations, PassionIOT empowers manufacturers to shift toward full automation with measurable gains in efficiency and accuracy.

Conclusion

Warehouse floors no longer just move products — they generate momentum. PassionIOT’s SMD storage system doesn’t merely support warehouse manufacturing; it redefines its tempo. For factories embracing change, these systems aren’t upgrades — they’re the new standard of movement.