In industries reliant on high-performance electronics, from renewable energy systems to 5G infrastructure, efficient thermal management is non-negotiable. Businesses seeking heat sink manufacturers that combine innovation, precision, and scalability often turn to specialized providers capable of addressing complex cooling challenges. Dingmetal, a prominent heat sink manufacturer with a focus on advanced materials and customization, has emerged as a global partner for companies prioritizing reliability and energy efficiency in their thermal solutions.

Material Mastery for Diverse Applications

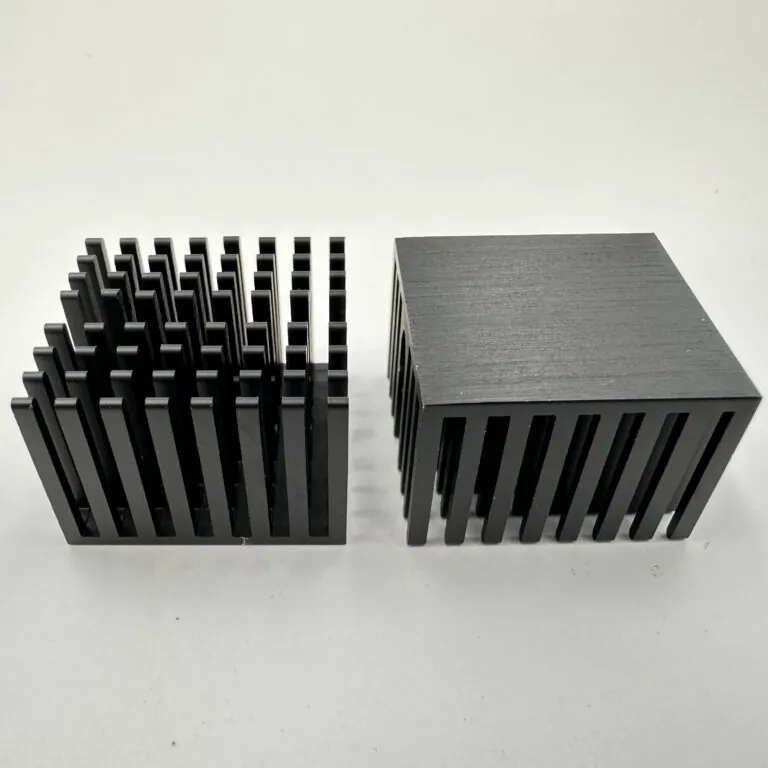

Dingmetal’s expertise spans a wide range of materials, enabling tailored heat sink designs for specific operational environments. For high-power LED lighting systems, the company utilizes extruded aluminum alloys to balance thermal conductivity and cost-effectiveness, while aerospace clients benefit from copper-based solutions engineered for extreme heat dissipation. A recent collaboration with a telecom equipment provider involved developing a liquid-cooled heat sink using aluminum-nitride ceramics, achieving an improvement in thermal transfer efficiency. This versatility ensures Dingmetal’s products meet the demands of industries where overheating risks compromise performance or safety.

A Commitment to Future-Ready Thermal Solutions

As industries evolve toward higher power densities and miniaturization, the role of an innovative heat sink manufacturer becomes increasingly pivotal. Dingmetal’s integration of advanced materials, precision engineering, and scalable production positions it as a forward-thinking partner for businesses aiming to stay ahead in competitive markets. By transforming thermal challenges into opportunities for efficiency gains, Dingmetal not only enhances device performance but also extends product lifespans—a testament to its mission of delivering cooling solutions that empower technological progress.