In the competitive world of garment manufacturing, staying ahead requires a balance of speed, quality, and material flexibility. Direct-to-Film (DTF) printing has emerged as a revolutionary digital solution that bridges the gap between traditional methods and modern demand. But what exactly is DTF, and why is it becoming the preferred choice for B2B textile providers?

What is DTF Printing?

DTF printing is a multi-step digital process where designs are printed onto a specialized PET film using pigmented inks. After printing, a hot-melt adhesive powder is applied and cured. The resulting transfer can then be heat-pressed onto nearly any fabric. Unlike Direct-to-Garment (DTG), which requires specific pretreatments, or sublimation, which is limited to polyester, a DTF textile printer offers a “print-on-anything” capability.

Key Advantages of the DTF Process

For businesses looking to optimize their production line, the transition to a high-end digital textile printer offers several distinct benefits:

Exceptional Fabric Versatility: DTF works seamlessly on cotton, polyester, nylon, treated leather, and even 50/50 blends, regardless of the fabric color.

Superior Durability: The bond created by the hot-melt powder ensures prints are highly stretchable and wash-resistant (up to 60°C), preventing the cracking often seen in vinyl transfers.

High ROI and Efficiency: By eliminating the need for screens or costly pretreatments, businesses can handle small-batch custom orders and high-volume runs with equal cost-effectiveness.

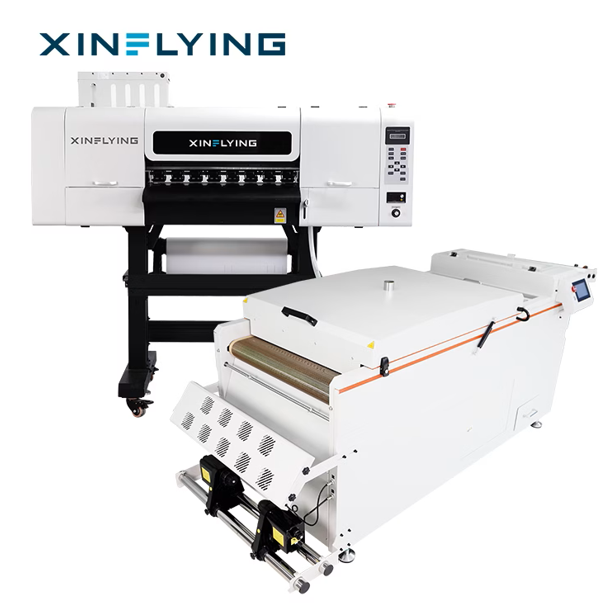

Professional Solutions from Xinflying

Xinflying provides robust hardware tailored for high-output environments. Their flagship C604+H6501 24-inch DTF Printer is a prime example of performance-driven engineering. Precise Specifications for Business Scaling:

Configuration: Equipped with 4pcs Epson i3200-A1 printheads for industrial stability.

Production Speed: Reaches up to 27m²/h in 4-pass mode, meeting tight B2B deadlines.

Precision Features: Includes an integrated auto-shaker, white ink circulation, and an imported mute rail for high-precision, noise-free operation.

By integrating Xinflying’s technology, manufacturers can deliver vibrant, photo-realistic details while maintaining the low overhead required for modern on-demand textile business.